About Diffuser3D

Trial and error leading to production

Production process

Diffuser3D production process

-

Declaration of Urgency

In April 2020, in response to the global spread of the new covid-19virus, there was a shortage of face shields in the medical field, and a vigorous campaign was launched in Japan to deliver face shields made by volunteers using FDM printers to the medical field.

2020/04

2020/04 -

Beginning of Production

We wondered if we could help in any way possible, so we started to make it using our LCD 3D printer.

2020/05

2020/05 -

Limitations of a 3D printer

During the process of making the face shield, I noticed that only one part of the face shield was thicker, and I realized that it was the part with the grid.

2020/05-1

2020/05-1 -

Diffuser Improvements

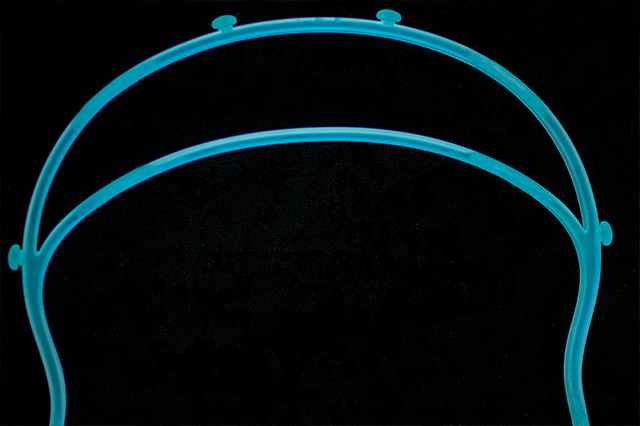

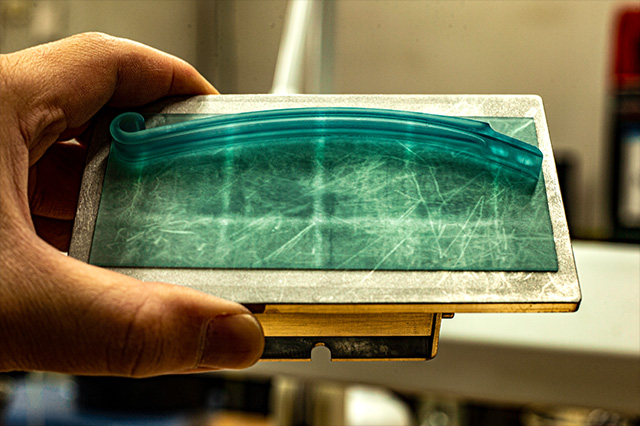

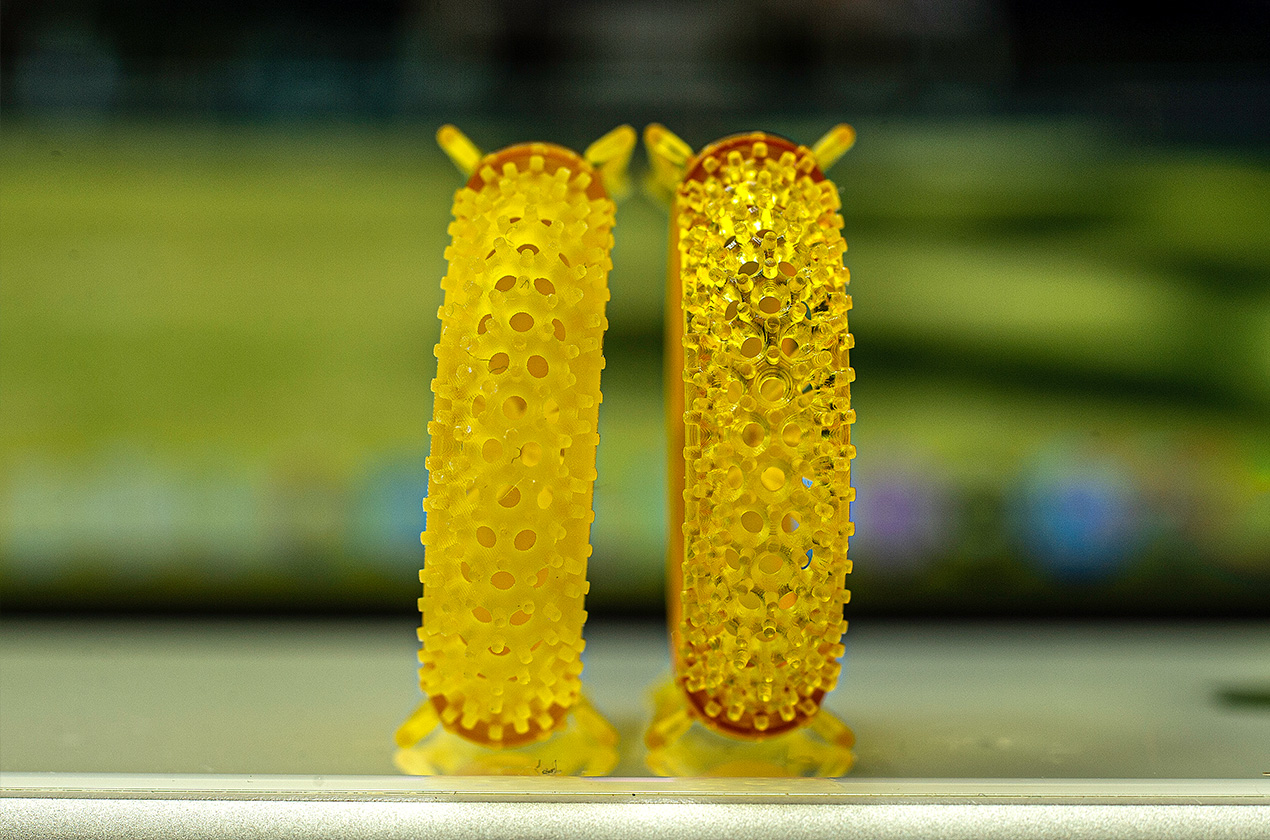

This is a picture of the beginning of it all. The pixel marks and layer bumps are no longer noticeable, and the unevenness of the LED light is reflected in the sculpted object.

2020/5-2

2020/5-2 -

Improvement results

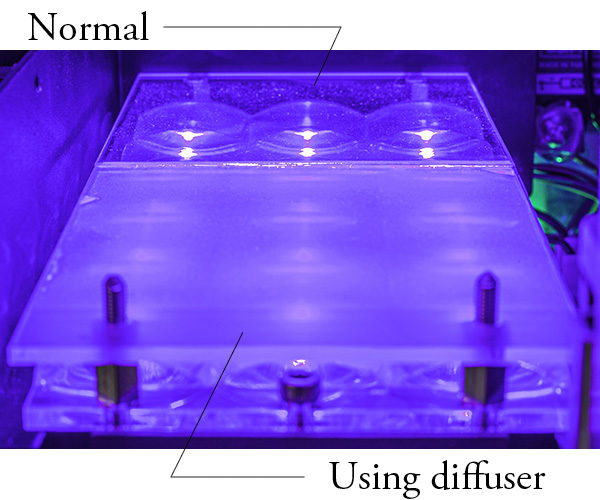

We used a diffuser to improve it, and after much trial and error and testing, we've come to the present. This is what Diffuser3D is all about.

After Improvement ◀ ▶ Before Improvement

2020/5-3

2020/5-3 -

Productions

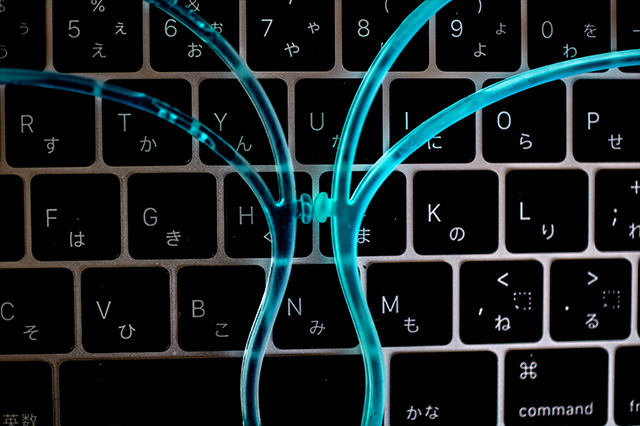

Originally we were only using it for ourselves, but we decided to sell it because we knew that there are always people in the world who have the same problem.

Current Issues

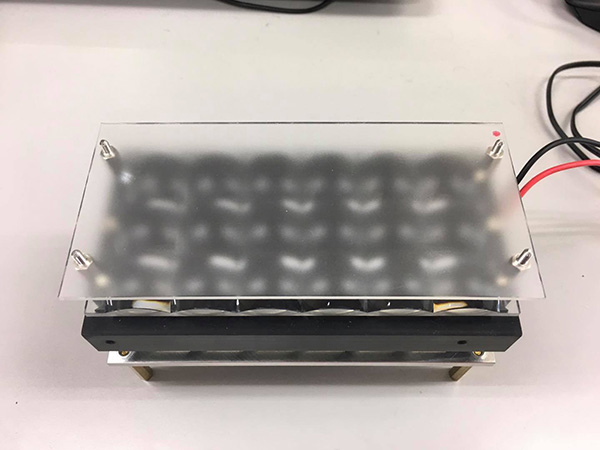

Unfortunately, not all LCD printers and resins are compatible with this product.

We are currently aligning it to work with Phorozn printers and some printers that have Matrix LEDs.

We have also reported in user testing that some of the regins do not give good results.

Finally, we hope the diffuser will be useful in your 3D printing life.

About Diffuser?

A diffuser is a component that improves the unevenness of the UV light unit's brightness by using a square or hexagonal optical lens called a ParaLED or MatrixLED, which is used in LCD printers with RGB or monochrome LCDs.

Pixel marks and layer bumps will be less noticeable, and the whole thing will look nice and shiny.

This is a special process that diffuses the light consistently, so the amount of light will not drop drastically, but for monochrome LCDs, the exposure time needs to be increased by 10-20%. Please note that depending on the resin, the effect may be difficult to achieve.

All parts are made in Japan, so you can use it with confidence.

Handling Products

| Phrozen 5.5inch -new release- |

LCD ParaLED v2.0 Early model with 3×5 hexagonal lens Price including tax)5,100円 |

|---|---|

| Phrozen 5.5inch |

ParaLED Late ParaLED V2.0 ParaLED V3.0 Model with square lens 3×6 Price including tax)5,000円 |

| Phrozen 6.1inch |

MonoLCD ParaLED V2.0 ParaLED V3.0 model with 4×6 square lens Price including tax)5,000円 |

| Elegoo Saturn 8.9inch |

mono4K LCD MatrixLED Quadrangle Lens 6×9 Price including tax)12,000円 |

| Phrozen XLseries 8.9inch |

LCD mono4K LCD ParaLED V2.0 ParaLED V3.0 model with 6x9 square lens Price including tax)12,000円 |

| Phrozen 13.3inch (in preparation) |

LCD mono4K LCD ParaLED V2.0 with 8×15 square lens Price including tax)22,000円 |

■ Click here to order ■

Shipping out of Japan ▶▶▶ Click here

国内向けECサイト ▶▶▶ こちら